Rebates & Special Offers

Pay as low as 0% for up to 48 months* or choose a $2,500 USD* rebate on Bobcat T595 compact track loaders.

|

General Info

|

|

|---|---|

| Condition: | Showroom |

| Manufacturer: | Bobcat |

| Model: | T595 |

| Machine Type: | Compact Track Loader |

| Coupler: | Bob-Tach |

|

Engine

|

|

|---|---|

| Horsepower: | 70.0 |

| Emissions: | Tier 4 |

|

Performance

|

|

|---|---|

| Rated Operating Capacity (ISO): | 2,280 lb |

| Tipping Load: | 6,517 lb |

| Operating Weight: | 8022 lb |

| Height to Bucket Hinge Pin: | 119 IN. |

|

Hydraulics

|

|

|---|---|

| Aux. Standard Flow: | 17.1 GPM |

|

Dimensions

|

|

|---|---|

| Width: | 67 IN. |

| Turning Radius: | 80 in |

| Fuel Tank: | 36.5 GAL. |

Description

Bobcat T595 Compact Track Loader

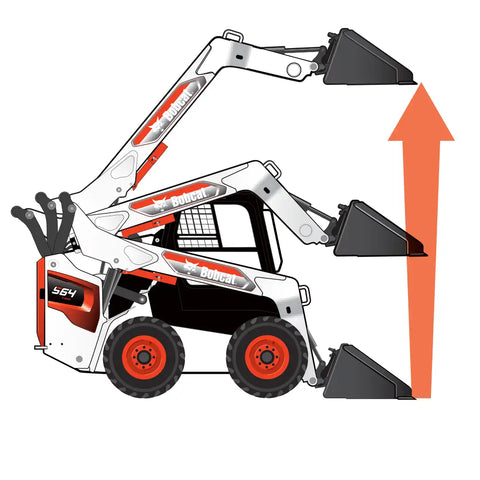

The Bobcat T595 compact track loader has the highest horsepower and Rated Operating Capacity (ROC) in the popular 500 frame size. This vertical path loader provides recognizable power in digging and pushing applications

- Standard Selectable Joystick Control

- You won’t find a tougher track system

- Powerful hydraulic performance

- Cold weather engine protection

Specs

| Rated Operating Capacity | 2,200 lb |

|---|---|

| Operating Weight | 8,022 in |

| Ground Pressure - Rubber Track | 5.1 psi |

| Auxiliary Standard Flow | 17.1 gal/min |

| Emissions Tier | Tier 4 |

|---|---|

| Engine Fuel | Diesel |

| Horsepower | 70 hp |

| Turbocharged Engine | Yes |

| Rated Operating Capacity | 2,200 lb |

|---|---|

| Operating Capacity - 50% of Tip | 3,142 lb |

| Tipping Load | 6,517 lb |

| Operating Weight | 8,022 lb |

| Travel Speed | 7.1 mph |

| Ground Pressure | 5.1 psi |

| Auxiliary Standard Flow | 17.1 GPM |

|---|---|

| System Relief @ Quick Couplers | 3,550 PSI |

| Length | 133 in |

|---|---|

| Length without Attachment | 104.5 in |

| Length with Standard Bucket | 133 in |

| Width | 67 in |

| Width with Bucket | 68 in |

| Height | 77.8 in |

| Height to Bucket Hinge Pin | 119 in |

| Reach @ Maximum Height | 23.5 in |

| Turning Radius | 80 in |

| Length of Track on Ground | 54.1 in |

| Track Width | 15.7 in |

Features

DRIVE RESPONSE MODE

Drive response mode allows you to choose how the drive responds to joystick movement. Whether you like a more gradual response, quicker response or something in between, three different settings put you in control.

SPEED MANAGEMENT

Simply “dial in” your required travel speed in small increments to match speed to your operation requirements and maximize attachment performance. Speed management gives you a full range of joystick motion with maximum driveline torque and full hydraulic power at slower machine speed.

STEERING DRIFT COMPENSATION

Steering drift compensation keeps you on a straight path by helping you make minor adjustments to the steering. It’s beneficial when you side-shift certain attachments, such as planers or trenchers, as this will tend to pull the machine to one side. You can also use it while driving on surfaces that cause the loader to gradually drift left or right, such as crowned roads. Make fine steering adjustments to either side and stay on target.

HORSEPOWER MANAGEMENT

Bobcat horsepower management automatically adjusts the loader drive system to maximize pushing and digging power while minimizing your chance of stalling. Unlike other anti-stall systems, Bobcat horsepower management lets the operator obtain maximum engine and drive torque to match the toughest digging conditions. If you prefer to work without it, simply disengage with the push of a button.

Rebates & Special Offers

Pay as low as 0% for up to 48 months* or choose a $2,500 USD* rebate on Bobcat T595 compact track loaders.

|

General Info

|

|

|---|---|

| Condition: | Showroom |

| Manufacturer: | Bobcat |

| Model: | T595 |

| Machine Type: | Compact Track Loader |

| Coupler: | Bob-Tach |

|

Engine

|

|

|---|---|

| Horsepower: | 70.0 |

| Emissions: | Tier 4 |

|

Performance

|

|

|---|---|

| Rated Operating Capacity (ISO): | 2,280 lb |

| Tipping Load: | 6,517 lb |

| Operating Weight: | 8022 lb |

| Height to Bucket Hinge Pin: | 119 IN. |

|

Hydraulics

|

|

|---|---|

| Aux. Standard Flow: | 17.1 GPM |

|

Dimensions

|

|

|---|---|

| Width: | 67 IN. |

| Turning Radius: | 80 in |

| Fuel Tank: | 36.5 GAL. |